Predictive Maintenance Workflow Challenges and Fixes

Key Takeaways:

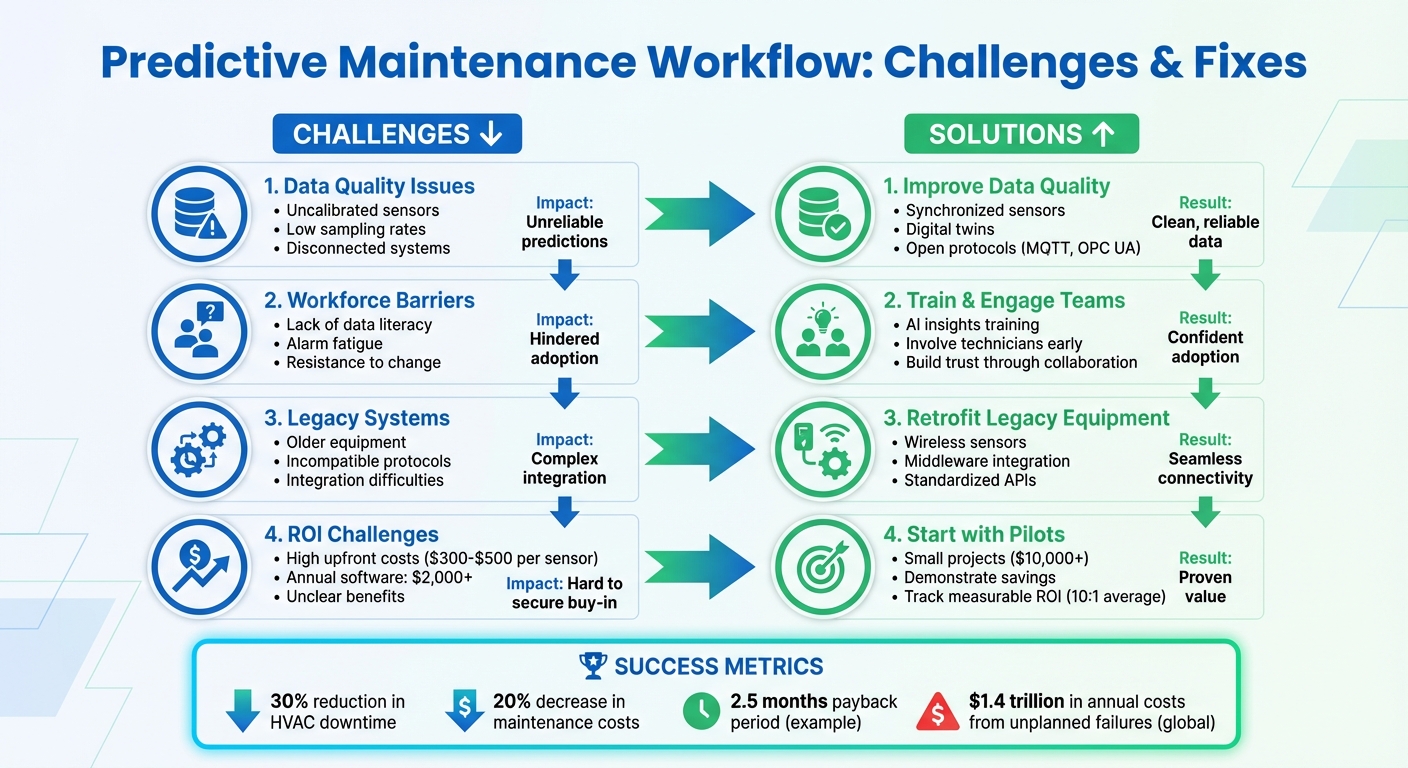

- Data Issues: Uncalibrated sensors, low sampling rates, and disconnected systems lead to unreliable predictions.

- Workforce Barriers: Lack of data literacy, alarm fatigue, and resistance to change hinder adoption.

- Legacy Systems: Older equipment and incompatible protocols complicate integration.

- ROI Challenges: High upfront costs and unclear benefits make it hard to secure stakeholder buy-in.

Solutions:

- Improve data quality using synchronized sensors, digital twins, and open protocols.

- Train technicians on AI insights and involve them in the process to build trust.

- Retrofit legacy equipment with wireless sensors and use middleware for integration.

- Start with small pilot projects to demonstrate measurable cost savings and ROI.

Example: A real estate firm reduced HVAC downtime by 30% and maintenance costs by 20% within six months of implementing PdM.

Predictive maintenance works best when supported by clean data, skilled teams, and scalable systems. Tools like CoreCast simplify this process by integrating sensor data, automating work orders, and providing actionable insights across portfolios. This data allows managers to benchmark real estate portfolios to identify underperforming assets.

Predictive Maintenance Challenges and Solutions Overview

AI, Predictive Maintenance & Future of PropTech – With Joe Stockton, Oyster Data

sbb-itb-99d029f

Common Challenges in Predictive Maintenance Workflows

While predictive maintenance holds great potential, implementing and scaling it comes with its fair share of obstacles. Real estate teams often encounter specific challenges that hinder both execution and scalability. Let’s dive into the key issues.

Data Quality and Integration Issues

One of the biggest hurdles in predictive maintenance is poor data quality. Maintenance records, equipment manuals, and sensor data are often stored in disconnected systems - some digital, others still on paper. These silos slow down diagnostics and can lead to mistakes, like ordering the wrong parts [5].

Sensor data adds another layer of complexity. Problems like unsynchronized timebases, uncalibrated sensors, and improperly timestamped readings can lead to "phase drift", where artificial intelligence (AI) misinterprets signals and detects false patterns [1].

On top of that, intermittent data collection creates blind spots. Wireless sensors often sample at low frequencies to save battery life, which means they might miss early warning signs, such as subtle vibration changes or high-frequency peaks [1][6]. Without extra contextual details - like load, speed, or ambient conditions - this raw data can "contaminate" machine learning models, making predictions unreliable [10]. As Andrew Froehlich, Founder of West Gate Networks, explains:

AI consistently produces accurate outcomes only when the data it analyzes and uses to make decisions is of high quality [4].

Another issue is the lack of labeled historical data that represents known fault modes. Without it, AI struggles to differentiate between minor anomalies and serious failures [1]. These data challenges contribute to the staggering $1.4 trillion in annual costs from unplanned equipment failures worldwide [10].

Workforce Adoption and Skills Gaps

Even with high-quality data, predictive maintenance programs can falter if the workforce isn’t prepared. Many technicians excel in mechanical skills but lack the data literacy needed to interpret analytics, sensor outputs, or AI insights [5].

Alarm fatigue is another common problem. When AI systems generate too many false positives, technicians start ignoring alerts altogether - even the critical ones [1][6]. This trust issue worsens when reliability teams are excluded from the initial design and implementation phases, leaving them disconnected from the process [1].

Resistance to change is also a factor. Many teams are comfortable with their existing reactive or preventive routines and approach digital workflows with skepticism [6]. Without user-friendly interfaces that translate predictions into actionable tasks, the gap between data insights and practical application remains too wide, making adoption difficult.

Legacy System Integration Problems

Older facilities bring their own set of challenges. Many legacy systems weren’t designed for real-time data sharing or cloud-based analytics. They often lack modern communication standards like OPC UA or MQTT, making it tough to integrate with IoT devices [5][10]. Maintenance records, meanwhile, are often locked away in proprietary systems or physical files, creating additional data silos [5].

Bringing these systems up to speed usually requires costly middleware, infrastructure upgrades, or complex APIs [5]. Physical limitations of older machines can also make it hard to place sensors in optimal positions, leading to incomplete or noisy data [1].

Security is another concern. In 2023 alone, manufacturing firms experienced over 300 data breaches, exposing more than 87.7 million records. Connecting outdated systems to the internet without proper safeguards significantly increases these risks [6].

ROI Justification and Budget Constraints

Convincing stakeholders to invest in predictive maintenance can be a tough sell. Decision-makers often hesitate because the benefits - like avoiding failures - are hard to quantify upfront. The initial costs can also seem high: sensors typically cost between $300 and $500 each, and annual software subscriptions start at $2,000 [6].

However, starting small can make a big difference. For example, a pilot project for a stamping press at an automotive plant paid for itself in just 2.5 months, preventing five weeks of downtime and saving $500,000 in maintenance costs [6]. Proof-of-concept projects can be launched for as little as $10,000, offering a manageable way to demonstrate value before scaling up [6].

| Challenge | Impact on Operations | Root Cause |

|---|---|---|

| Data Quality Issues | Missed failures; unreliable predictions | Unsynchronized sensors; low sampling rates [1][5] |

| Skills Gaps | Underutilized tools; misdiagnoses | Lack of data literacy among technicians [5] |

| Legacy Systems | Integration difficulties; noisy data | Outdated hardware; incompatible protocols [5][10] |

| Budget Constraints | Delayed approvals; limited pilots | High upfront costs; unclear ROI [6] |

Fixes for Predictive Maintenance Challenges

The challenges in predictive maintenance might seem daunting, but there are straightforward solutions to tackle them. Real estate teams don’t need to revamp everything at once. Instead, targeted strategies can address specific issues while paving the way for broader adoption.

Improving Data Quality and Integration

Clean, well-integrated data is the backbone of any predictive maintenance program. Start by establishing clear data governance protocols. This means synchronizing timebases, standardizing sampling rates, and setting validation thresholds to ensure data accuracy and avoid phase drift [1].

For facilities dealing with scattered documentation, 3D digital twins can be a game-changer. These models connect manuals, logs, and sensor data directly to asset representations, making information easily accessible [5]. When it comes to sensors, consider a mixed approach: install wired, high-fidelity sensors on critical infrastructure like main HVAC chillers and use cost-effective wireless sensors for less critical equipment [1].

Bridging the gap between older systems and modern AI platforms is possible with middleware and open protocols like MQTT, OPC UA, and REST APIs [10][5]. IO-Link technology can also simplify things by gathering multiple process values (e.g., temperature and vibration) from a single sensor, cutting down on both hardware costs and complexity [6]. To protect data integrity, isolate IoT devices from the main property network using network segmentation to minimize cyber threats [4].

Before committing to a vendor, audit your current data collection and storage systems. Identify any gaps in machine health information so you can address them effectively [6]. Once the data issues are resolved, the focus can shift to equipping teams to act on these insights.

Addressing Workforce Skills and Adoption Barriers

Predictive maintenance enhances, rather than replaces, the expertise of maintenance teams. Start by forming multidisciplinary groups that bring together reliability, operations, and IT staff to ensure shared ownership of the program [1]. Use Explainable AI (XAI) dashboards to show technicians exactly which factors - like frequency peaks or current harmonics - triggered an alert. This builds trust by linking AI insights to real-world engineering [1].

Treat your maintenance staff as partners in training AI systems. By allowing technicians to recalibrate thresholds based on their feedback, you can reduce false alarms and boost program acceptance [1]. The "I Do, We Do, You Do" method is a practical way to ease teams into new processes. Experts lead initially, then work alongside staff, and finally hand over operations to the internal team [11].

Focus training efforts on data literacy. Teach teams how to interpret AI outputs instead of just operating hardware [6]. Digital twins can also serve as virtual training tools, letting staff practice with equipment and procedures in a risk-free environment [7]. Additionally, integrate predictive insights into existing Computerized Maintenance Management Systems (CMMS). This automates work orders and provides clear, actionable repair instructions [8].

Simplifying Legacy System Integration

Modernizing older infrastructure doesn’t require a complete overhaul. Retrofit wireless sensors can bring legacy equipment online without replacing entire systems [2][5]. These sensors provide the real-time data needed for AI analysis, even when older machines lack native connectivity.

Leverage open APIs to extract historical data from ERP and CMMS systems, automating work orders in the process [5]. Middleware can connect SCADA systems to stream real-time equipment status, while standardized data formats like JSON, CSV, or XML ensure compatibility across platforms [5]. Start with read-only data flows to validate connections before moving to full bi-directional syncing and automation.

Demonstrating ROI with Pilot Projects

The quickest way to gain stakeholder approval is by showing tangible results. Pilot projects act as proofs-of-concept, addressing data, workforce, and integration challenges while delivering measurable outcomes. Begin with three to five high-impact assets, such as HVAC compressors or elevator motors [2][6]. Focus on assets with frequent failures rather than those that rarely fail but are critical. Frequent failures generate more data, enabling quicker refinements and faster results - often within six to twelve months [11].

Track metrics to demonstrate value, such as Payback Period (Initial Investment / Annual Net Savings) and Net Present Value (NPV), to justify financial investment [5]. Define KPIs early, including Mean Time Between Failures (MTBF), Mean Time to Repair (MTTR), and the ratio of planned to reactive maintenance [7]. These metrics turn abstract benefits into concrete improvements.

Pilot projects don’t have to break the bank. Costs can start as low as $10,000, with annual software subscriptions around $2,000 and individual sensors costing $300 to $500 each [6]. Considering that unplanned downtime can cost $22,000 to $260,000 per minute, even a small pilot can deliver significant returns. Predictive maintenance typically achieves an average ROI of 10:1 within 12 to 18 months [2].

Using CoreCast for Predictive Maintenance Automation

CoreCast takes predictive maintenance to the next level by combining essential functions like asset tracking, performance monitoring, and maintenance management into a single, unified platform. Instead of juggling multiple systems, teams can now handle all these operations seamlessly in one place. This integrated approach helps break down data silos, which are often the root cause of delays in maintenance workflows.

One standout feature of CoreCast is its integrated mapping tool, which offers a clear, visual representation of an entire portfolio alongside the competitive landscape. With this tool, teams can pinpoint properties housing critical equipment, track sensor data geographically, and prioritize maintenance efforts based on both location and the importance of the assets. If a piece of equipment starts showing early signs of failure, teams can quickly assess its context within the broader portfolio, enabling smarter decisions about repairs or replacements. This mapping tool works hand-in-hand with CoreCast's real-time dashboards, ensuring all data is immediately actionable.

What truly sets CoreCast apart is its real-time data integration. The platform brings together sensor feeds, historical performance records, and operational metrics into dashboards that update automatically. This allows property managers to monitor crucial systems like HVAC units, elevators, and other key infrastructure without needing to toggle between multiple software tools. By consolidating this data, CoreCast makes it easier to identify patterns that could signal upcoming equipment failures.

CoreCast also provides insights across entire property portfolios, helping teams identify trends and generate detailed reports for stakeholders. These reports can justify expenditures to investors or ownership groups by highlighting which building types or equipment brands require extra attention. This level of analysis can guide smarter purchasing decisions and better budget planning in the future.

Looking ahead, CoreCast is set to integrate with property management systems, further enhancing its proactive asset management capabilities. While CoreCast itself isn't a property management tool, its ability to connect with such systems ensures a smoother, more streamlined maintenance workflow, reinforcing its role as a key player in predictive maintenance automation.

Implementation Roadmap for Real Estate Teams

Asset Inventory and Sensor Deployment

Begin by conducting a thorough audit of your key mechanical, electrical, and plumbing (MEP) systems. Identify and prioritize assets based on how often they fail, the cost of repairs, and their overall impact. For pilot programs, focus on assets with frequent issues, like small conveyor motors or older HVAC units, to quickly validate your approach [11][2].

Next, deploy IoT sensors designed for specific failure types. For instance, use vibration sensors for rotating equipment like motors and pumps, thermal sensors for electrical panels, and pressure or acoustic sensors to detect leaks in plumbing or HVAC systems [2][3]. Opt for high-fidelity wired sensors for critical assets, while using cost-effective wireless sensors for less critical or older systems [1]. Once sensors are in place and data collection begins, you can move on to developing AI models for failure detection.

Building AI Models for Failure Detection

Start by establishing a baseline of normal operations using real-time sensor data. Unsupervised machine learning can help detect anomalies initially, while supervised models become more effective as failure data accumulates [1][2]. This phase, which typically takes 9 to 12 weeks, involves importing historical maintenance records, training baseline models, and fine-tuning alert settings [2].

Data governance plays a crucial role here. Before deploying your AI models, ensure that all sensors are synchronized by aligning timebases and standardizing sampling rates. This prevents phase drift and avoids misleading correlations in your data [1]. Use explainable AI (XAI) dashboards to clarify which features - like a specific frequency spike - trigger alerts, helping technicians trust and understand the system [1].

Automating Alerts and Work Orders

Once your AI models are reliable, integrate sensor feeds with CoreCast to automate work orders based on severity thresholds. CoreCast’s real-time dashboards can consolidate sensor data, historical performance records, and operational metrics. Its mapping tool helps prioritize maintenance tasks by location and asset importance, enabling faster responses when equipment shows early warning signs [2]. Software agreements typically start at around $2,000 annually [6].

Scaling and Continuous Improvement

To scale effectively, build on your initial successes. Start with 10–20% of your portfolio and track 10–15 key metrics, such as emergency repair rates and mean time between failures (MTBF), to validate your approach before expanding further [12][5]. Dedicate 30–40% of your resources to change management and workforce training to create a sustainable advantage [12][11].

Provide technicians with 60 to 80 hours of structured training to ensure they can confidently interpret AI-generated insights. As you expand to include a broader range of assets, continuously update your AI models with new data and regularly assess system performance to uncover additional opportunities for improvement [6][2].

Conclusion

Predictive maintenance marks a shift from reacting to problems as they arise to proactively managing assets. This approach can reduce equipment downtime by 30% and cut annual maintenance costs by nearly 20% within just six months - all while helping avoid the massive expenses tied to unplanned downtime [9][6].

To make this transition successful, key steps include improving real estate data management, synchronizing sensors, launching targeted pilot programs, and investing in workforce training. As Dr. Howard Penrose, President of MotorDoc LLC, wisely points out:

Predictive maintenance should be viewed not as an autonomous solution but as an evolutionary process - one that augments, rather than replaces, the expertise of the maintenance professional [1].

Addressing the challenge of fragmented data, CoreCast offers a solution by integrating sensor feeds, historical performance data, and operational metrics into real-time dashboards. These dashboards provide a clear, centralized view, allowing teams to prioritize tasks based on criticality, automate work orders when severity thresholds are met, and allocate resources more effectively. This streamlined system not only improves day-to-day operations but also sets the stage for the strategic advancements discussed in the next section.

Allocating 30–40% of resources to change management and workforce training ensures predictive maintenance systems can reach their full potential [12]. Starting with pilot projects focused on high-impact assets allows teams to quickly demonstrate measurable ROI, as evidenced by the successes highlighted earlier.

FAQs

Which assets should we start with for a PdM pilot?

When planning a predictive maintenance (PdM) pilot, it's smart to prioritize assets that carry high failure risks and offer measurable condition data. These types of assets provide the best foundation for a scalable and reliable PdM strategy.

Great candidates for a PdM pilot include:

- Rotating equipment: Motors, pumps, and turbines often show measurable signs of wear before failure.

- Electrical systems: Switchgear, transformers, and circuit breakers can be monitored for issues like overheating or insulation breakdown.

- Hydraulics: Pressure drops or fluid contamination are clear indicators of potential problems.

- Conveyors: Belt misalignments, motor strain, or unusual vibrations signal wear and tear.

- Utilities: Systems like HVAC or compressed air often have predictable patterns that can be monitored effectively.

Focusing on these critical assets ensures that your PdM efforts deliver the most impact, improving both reliability and efficiency from the start.

How do we reduce false alarms and rebuild technician trust?

To cut down on false alarms and regain technician trust, it’s crucial to fine-tune your monitoring systems. Start by ensuring sensors are correctly placed and calibrated to avoid interference and misinterpreting minor, non-critical changes. Enhance data filtering methods and integrate contextual details, such as operational history and surrounding conditions, to improve accuracy.

Regular updates to AI models and alert thresholds are essential - use feedback from technicians to make these adjustments meaningful. Finally, open and honest communication with your team is key. Keeping technicians informed about how predictive maintenance tools work and addressing their concerns can go a long way in building confidence in these systems.

What’s the fastest way to connect legacy equipment to PdM?

The fastest way to bring legacy equipment into a predictive maintenance (PdM) setup is by retrofitting it with sensors and using standardized communication protocols. This approach gathers data from your current machinery without the need for costly replacements. By installing retrofit sensors and edge computing gateways on existing assets, you can transmit data directly to your PdM system. This enables real-time analytics, making it a practical and budget-friendly solution that maximizes the value of your existing equipment.